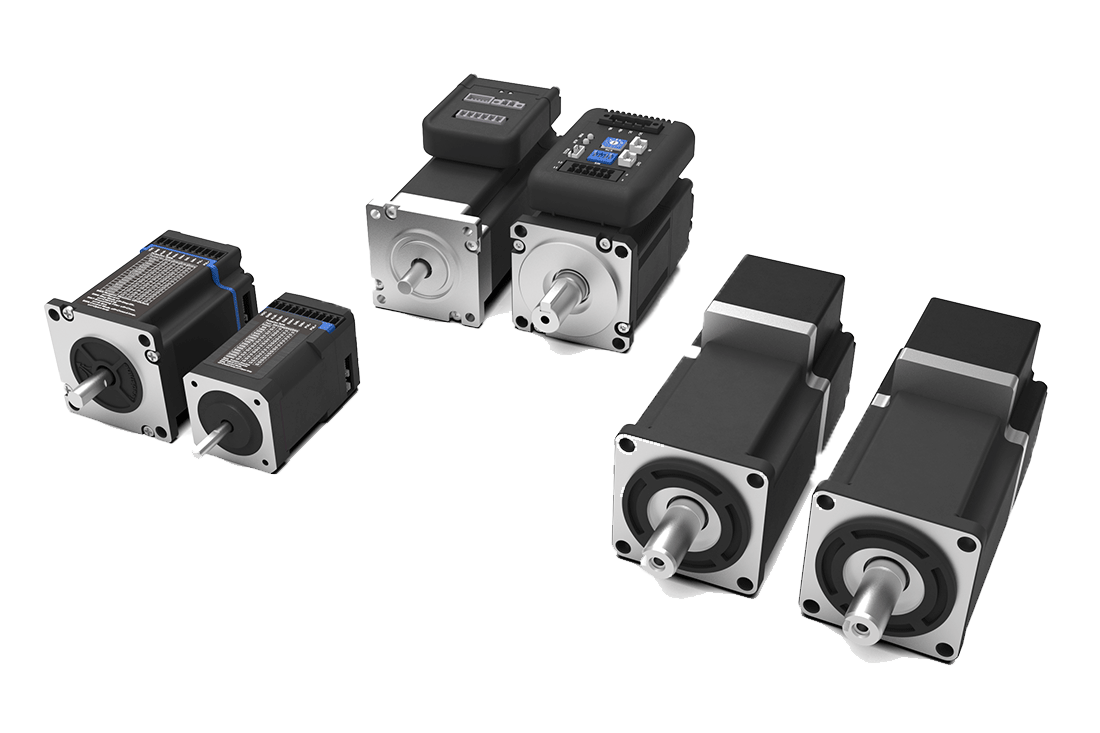

Motion control systems are integral to various industries, from robotics to manufacturing, automotive, aerospace, and medical devices. When it comes to choosing the right motor for your applications, understanding the difference between stepper motor and servo motor is essential. At Leadshine, we specialize in providing cutting-edge solutions that meet your motion control needs. In this article, we will delve into the key differences between these two types of motors and how they impact motion control systems.

What Sets Stepper Motors Apart from Servo Motors?

When selecting a motor for a motion control system, it’s crucial to understand the operational differences between stepper motors and servo motors. Stepper motors are known for their ability to move in discrete steps, making them ideal for applications that require precise control over position. They excel in open-loop control systems, where feedback isn’t necessary. On the other hand, servo motors are typically used in closed-loop systems, where the motor is continuously monitored and adjusted to maintain optimal performance.

Stepper motors are usually more affordable and simpler to implement, making them a popular choice for applications where high torque and position accuracy are needed without the complexity of feedback systems. However, servo motors are more efficient in high-performance settings where dynamic adjustments are crucial. They offer higher speeds and smoother motion with a more precise control over the speed, position, and torque, making them ideal for demanding applications.

Applications of Stepper Motors and Servo Motors in Motion Control Systems

The choice between stepper motors and servo motors in motion control systems largely depends on the application’s specific needs.Leadshine provides both types of motors, enabling customers to choose the most suitable option for their systems.Stepper motors are often used in 3D printers, CNC machines, and other devices that need to operate with a fixed, predictable movement. Meanwhile, servo motors are typically found in robotics, conveyor belts, and other applications requiring fast, smooth, and energy-efficient performance.

Choosing the right motor for your system can greatly affect the overall efficiency and accuracy of the application. Stepper motors are often the better choice for applications that prioritize precision over speed, while servo motors are better suited for applications where high performance and speed are required.

Conclusion

In conclusion, understanding the difference between stepper motor and servo motor is key to making an informed decision when designing or upgrading your motion control systems. At Leadshine, we provide both stepper motors and servo motors tailored to meet the unique needs of your applications. Whether you’re looking for affordability, precision, or high performance, we have the solutions you need to optimize your motion control systems. Be sure to assess your system's requirements carefully to select the right motor for the job and maximize efficiency.